Execution standards:JC/T529-1995

Main components:Bentonite

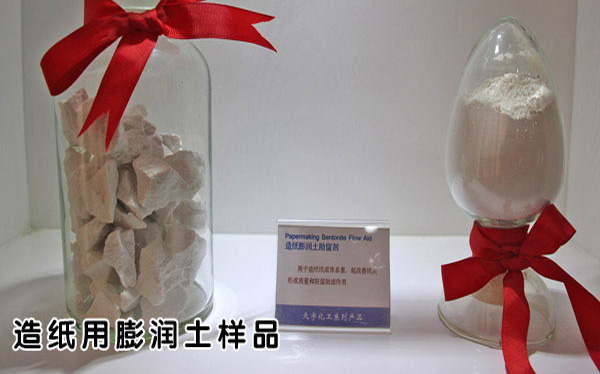

Product appearance:Off white powder

Main purpose: To improve the retention of fine substances, enhance the filtration speed of the mesh, improve the forming quality of paper, and increase the whiteness of paper.

Bentonite used in papermaking has the advantages of fine particle size, high purity, good whiteness, strong cation exchange capacity, good water absorption and expansion, good suspension, and a wide range of suitable acidity and alkalinity. When it expands in contact with water, its volume and specific surface area can increase several times. Its main component, montmorillonite, has a negative charge on the micro crystal surface and a positive charge on the edge end face. When combined with cationic polymers, it can achieve good retention and filtration effects.

The main functions of bentonite for papermaking are:

1.Improve the retention of small substances and reduce the concentration of white water;

2、Improve the filtration speed of the network section;

3、Improve the distribution of ash and various additives;

4、Improve the forming quality of paper sheets;

5、Fix the adhesive and resin, balance the anionic adhesive;

6、Clean the paper machine and improve its operational performance;

7、Reduce fiber and chemical auxiliary material consumption, and lower overall costs;

Adding a certain amount of high whiteness bentonite filler to the paper industry can maintain stable wet end conditions, improve the pigment dispersion, uniformity, surface smoothness, opacity, and paper uniformity of the paper, and significantly increase the paper's fracture and tear index. Bentonite can improve the retention rate of fine fibers, fillers, and wet end chemical additives in pulp, reduce sediment formation, inhibit and mold, avoid pulp decay, save raw material costs, effectively reduce pulp consumption, decrease white water concentration and emissions, and reduce pollution.

- Our company has successfully returned from participating in the China Import and Export Fair

- Our company participated in a seminar on summarizing and analyzing the contamination of feed mycotoxins

- Colleagues from the domestic feed industry visited and inspected Inner Mongolia Ningcheng Tianyu Bentonite Technology Co., Ltd

- Ningcheng Tianyu Bentonite has once again been recognized as a "Vice Chairman Unit" by the Bentonite International Forum Special Committee

- Inner Mongolia Ningcheng Tianyu Bentonite Technology Co., Ltd. has officially become a member of the China Animal Nutrition Product Supplier Alliance

- What are the application scope of feed grade montmorillonite in animal husbandry?

- Our company carried out the sampling and preparation work for bentonite raw ore mining in 2015

- Our company achieved complete success at the Shenyang Feed Industry Exhibition